What is TFT-LCD and TFT-LCD process

what is TFT-LCD

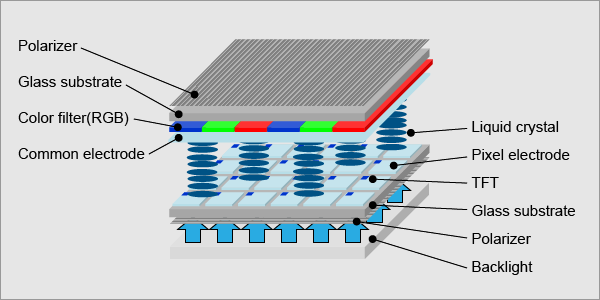

LCD consists of many pixels. One pixel includes three sub-pixels (red/green/blue, RGB). In the case of full HD resolution (which has been widely used in smart phones), there are more than 6 million (1,080 x 1,920 x 3=6,220,800) sub-pixels. In order to activate millions of sub-pixels, each sub-pixel needs a TFT. TFT is the abbreviation of "thin film transistor. TFT is a semiconductor device. It is used as a control valve to provide appropriate voltage for the liquid crystal of each sub-pixel. The TFT LCD has a liquid crystal layer between a glass substrate formed of a TFT and a transparent pixel electrode and another glass substrate having a color filter (RGB) and a transparent counter electrode. In addition, place the polarizer on the outside of each glass substrate, and place the backlight on the back. The variation of the voltage applied to the liquid crystal changes the transmittance of the panel including the two polarizers, thus changing the amount of light transmitted from the backlight to the front surface of the display. This principle enables TFT LCD to produce full color images.

TFT LCD

TFT-LCD process

The previous array

-The Array process in the previous section is similar to the semiconductor process, but the difference is that the thin film transistor is made with the glass manufacturer instead of the silicon wafer.

Midsection Cell

-The Cell in the middle section is based on the glass of the front section Array, combined with the glass substrate of the color filter, and liquid crystal (LC) is poured between the two glass substrates.

Module Assembly (module assembly)

-back module assembly process is a production operation that assembles the glass after the Cell process with other components such as the drive circuit IC, backlight board, iron frame, etc.